Meets ASTM, ANSI, D2000, REACH, NSF, ISO, RoHS, WEEE and IPC 1752-1, AS9100D, UL, TUV, NSF and others, as required. The Wests 1 Source for Cast Iron, Gratings and Fabrication When it comes to cast. Serving many different industries with offshore contract manufacturing, automation, OEM/ODM, engineering, product development, prototyping, pilot production, quality assurance and supply chain management services. Manufactures to a tolerance of +/-0.005 inches (0.127 mm). Call today or request a quote online for any casting service. Capable of casting parts up to 120 inches L x 120 inches W x 20 inches H dimensions (3000 x 3000 x 500mm) with weight up to 500 pounds (250 kilograms). Warner Brothers Foundry Company makes quality aluminum, bronze, brass and copper castings. Materials include metals (such as ductile iron, gray iron, carbon steel, stainless steel, iron, nickel, aluminum, brass, bronze, copper, titanium) and plastic resins (such as neoprene, ethylene-propylene, nitrile, silicone, styrene-butadiene, natural rubber, PPVC). Whether you have a design ready for casting, or you need a custom casting design, we can help.

Secondary processes include cleaning, normalizing, quenching, tempering, CNC machining, stamping, heat treatment, annealing, assembly, engineering, finishing, inspection, e-coating, heat treatment, layout, machining, painting, pattern repair, rigging, welding, shot blasting, polishing and metallurgical testing. Our ductile iron foundry is centrally located in Wichita, KS.

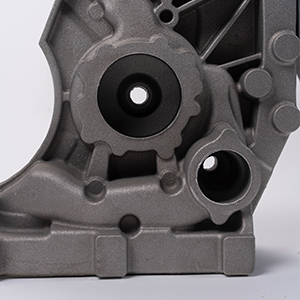

The process of producing custom cast iron parts 1.Custom precision casting from die, investment, sand, centrifugal, continuous and cold casting processes with high tensile strength, thin wall and corrosion, heat, abrasion, stress, acid and wear resistant. When you need a metal part that’s both accurate and inexpensive, metal casting is an ideal choice. Making wooden, resin, plastic, aluminum or iron patterns according to the samples, or drawings, and requirements of customers. After get the patterns, making rough iron castings by sand casting, or other casting processes. Richmond Iron makes custom sand castings in iron, bronze and aluminum using traditional and advanced digital methods.Marine parts and Sporting equipment parts.Fire Sprinkler Frames and Fire Sprinkler Parts.We specialize in a wide range of custom metal cast parts as mentioned above and include: Whatever type of casting you need, our staff at Deeco Metals and engineers at our casting foundry, will analyze your particular requirements and recommend the most effective and economical casting method, metal alloy. Contact Deeco Metals to schedule a consultation at 1-800-BRASS-84. And many other industrial and commercial cast metal parts Whatever type of casting you need, our staff at Deeco Metals and engineers at our casting foundry, will analyze your particular requirements and recommend the. Request a quote for custom metal castings. Request a quote for custom metal castings.Ī custom combination of design, casting and finishing is planned for each project to deliver the right casting. Contact Deeco Metals to schedule a consultation at 1-800-BRASS-84. We offer technical and design assistance to help ensure that your finished parts are as strong as they can possibly be. After the shell mold has completely cured, the cast. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. From this mold, a pattern is cast from a material that can melt or evaporatetypically wax. Our ductile iron foundry can make ductile iron casting in different grades, such as QT400-15, QT400-15, QT450-10, QT500-7. A replica pattern is used to create a mold out of rubber, metal, or resin. Deeco Metals specializes in several different casting methods learn more about our casting processes to learn which is the best choice for your part.

#CUSTOM IRON CASTING FOUNDRY QUOTES FULL#

Plating(all types such as Chrome, nickel, flash copper, brushed finish, oil bronze finish, etc.) Richmond Iron makes custom sand castings in iron, bronze and aluminum using traditional and advanced digital methods.In addition to the casting operation, we also offer value-added services such as full or partial machining components and surface conditioning such as: CFS Foundry is the top custom investment casting manufacturer in China. We also offer semi or fully assembled parts or sub-assemblies.

#CUSTOM IRON CASTING FOUNDRY QUOTES ISO#

Our foundries have established an effective quality assurance system and have ISO standard certifications that ensure parts are produced accurately and in compliance with ASTM & SAE standards.

Manufacturers first craft permanent molds using materials selected by the customer. Our plants use Optical Comparators, hand-held measuring devices, spectrometers and other quality or mechanical measuring equipment to inspect all the metal castings and parts Deeco sells to all our USA customers. The nature of the metal alloy used in the foundry product often determines.

0 kommentar(er)

0 kommentar(er)